It is recommended that you update your browser to the latest browser to view this page.

Please update to continue or install another browser.

Update Google Chrome

It is recommended that you update your browser to the latest browser to view this page.

Please update to continue or install another browser.

Update Google ChromeKasera's long time in the design and manufacture of air cooled heat exchangers means that our highly trained and experienced thermal design engineers are able to offer a bespoke solution to our customers in the design of their induced draft air cooled or forced draft air cooled heat exchangers, both thermally and mechanically.

Kasera Heat Exchanger Pvt. Ltd. makes use of leading company's computer equipment, including the latest Computer Aided Design systems, to ensure maximum efficiency in:

Kasera Heat Exchanger Pvt. Ltd. Plug & Cover Plate Header Air Coolers and Heat Exchangers for use in oil refineries, petrochemical plants, power generating stations, and fertilizer and gas production plants throughout the world.

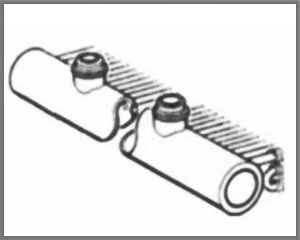

The welded bonnet header is used for ammonia condensers freon condensers and vacuum steam condensers. The advantage is the full welded construction suitable for vacuum applications.

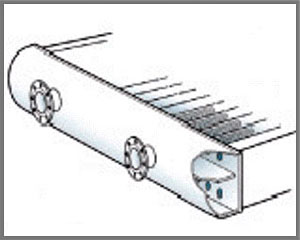

The pipe header is the most commonly used header type for working pressures up to 220 bar when no inner access is necessary in condenser, heat exchangers and air coolers. Finned tubes hair pins are assembled with TIG butt weld. The plughole opposite each tube allows the finned tube to be welded to the pipe. The welds are heat treated and X-ray tested.

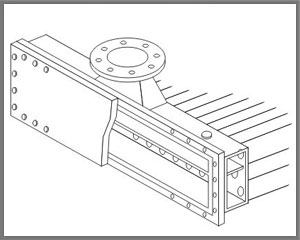

The plug header is the most commonly used header type for working pressures up to 350 bar in heat exchangers and air coolers. The plughole opposite each tube allows the finned tube to be expanded into the tube sheet. It also facilitates mechanical cleaning and plugging in case of leakage repairs, re-tubing and upgrading. . The welds are heat treated and X-ray tested. For hydrogen service at high pressure, seal welding or strength welding can be provided. This is less expensive than using pipe headers, which are generally employed with a service pressure above 200 bar.

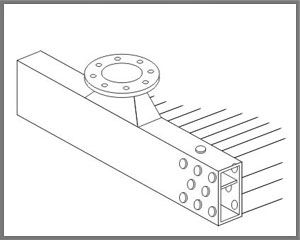

The manifold header is the most commonly used header type for allowable pressures drop is very low. This large manifold ensures an equal distribution of fluid flow in the tubes. The tube sheets are directly welded to the manifold. This type is used for vacuum steam condensers, heat exchangers and refrigeration units. The welds are heat treated and X-ray tested.

The Fin Tube is the core technology of the Air Cooled Heat Exchanger. Kasera's Heat Exchanger are available in a variety of fin tube configurations to suit the needs of the application. Condenser tubes are available in 1 to 2 inch or more diameters in combination with Crimped, Extruded, L Foot, KL Foot, LL Foot, Embedded, Edge, Soldered, Brazed, stamped and Welded fin types.

Kasera Heat Exchanger Pvt. Ltd. Re-Tubing and Repair of Tube Bundles for Heat Exchangers. Many repairs including the complete re-tubing of heat exchanger tube bundles, are offered. Our preference is to re-tube/refurbish in our own workshop where the work can be carried out under factory conditions. Where this is not possible on-site repairs can be arranged. We can supply helical high finned tube bundles in either welded finned tube, applied finned tube or extruded finned tube.

Kasera Heat Exchanger Pvt. Ltd. Supply full range of Spares and Replacement parts for use in Heat Exchangers, Process and Engine Cooler Systems throughout the world. Such as: